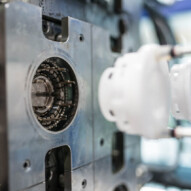

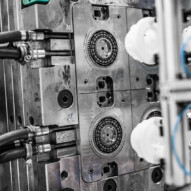

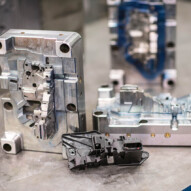

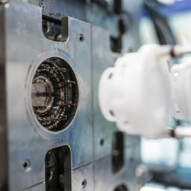

Plastics injection

Main manufacturing range

- manufacture of plastic components for automotive, electrotechnical and packaging industry

- manufacture of technical mouldings

- manufacture of injected plastic parts with specialization for business of cosmetic and food packaging

- assembling, final finishing operation, completion and packaging

- ultrasonic welding of injected plastic parts

Processed materials

All basic technical and consumer plastics: HDPE, LDPE, LLDPE, PP, PS, SAN, ABS, TPE, TPU, PMMA, POM, PA 6, PA 6.6, PA 11, PA 12, PBT, PC and others.

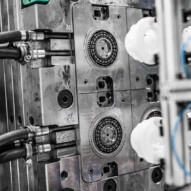

Technological equipment

- 46 injection moulding machines with closing power 50 – 1.400 tons (500 – 14.000 kN) from Engel, Wittmann-Battenfeld and Mitsubishi

- Heating equipment from Tool-Temp, Piovan, GWK a Wittmann

- Hot running regulators from Hasco, Feller, PSG, Synventive etc.

- Dry air driers from Motan, Moretto, TTW and so on

- System of vacuum raw material transportation from Motan and Moretto

- Equipped by separating belt conveyers for transportation and recycling of sprue waste, screw-running machinery and other handling facilities

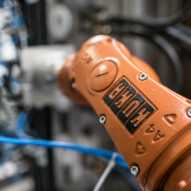

- Fully automatical by robots equipped work stations using In-Mould-Labeling (IML), Overmold (OVM) technologies and 2K injection.

Technical parameters

| Weight of injected plastic parts | from 3 g to 6 kg |

| Closing power | from 500 to 14.000 kN |

| Max. weight of tool | 21.000 kg |

| Max. dimensions of tool | 1.470 mm x 1.960 mm x 1.400 mm |

List of injection moulding machines

| Type of machine | Closing power [t] | Producer | Quantity |

|---|---|---|---|

| ENGEL WINTEC t-win 14000-11000 EU including robot Viper 40RC300 | 1.400 | Engel | 1 |

| ENGEL WINTEC t-win 10500-11000 EU including robot Viper 40RC300 | 1.050 | Engel | 1 |

| ENGEL Duo 3550/700 PICO including robot Viper 40RC200 | 700 | Engel | 1 |

| ENGEL VC 2460/400 including robot Viper 60 | 500 | Engel | 1 |

| ENGEL DUO 3550/700 PICO including robot Viper 40RC201 | 300 | Engel | 1 |

| ENGEL VC 2460/400 including robot Viper 60 | 400 | Engel | 1 |

| ENGEL VC 3550/400 Power including robot Wittmann W831 | 400 | Engel | 1 |

| ENGEL DUO 2550/400 including robot Viper 12 | 400 | Engel | 1 |

| ENGEL ES 2550/400 HL including robot ERC and ENGEL IML technology applied | 400 | Engel | 1 |

| BA Smart Power 350/1330 including robot Wittmann W831 | 350 | Battenfeld | 2 |

| BA Smart Power 300/1330 including robot Wittmann W831 | 300 | Battenfeld | 1 |

| ENGEL VC 2460/300 including robot Viper 12 | 300 | Engel | 1 |

| ENGEL VC 1800/300 Tech including robot ERC 23F | 300 | Engel | 1 |

| ENGEL VC 1800/300 Tech including robot Viper 20EP8 | 300 | Engel | 1 |

| ENGEL VC 1800/300 Tech including robot Viper 12 | 300 | Engel | 1 |

| BA 300/1000H/60V HM including 6 axis robot KUKA KR6 and BATTENFELD 2K technology applied | 300 | Battenfeld | 1 |

| BA 300/330 including robot Wittmann W818 | 300 | Battenfeld | 1 |

| EM 260 SPV-2 including robot Wittmann W818 | 260 | Chen Hsong | 1 |

| BA Smart Power 240/1000 including robot Wittmann W818 | 240 | Battenfeld | 1 |

| ENGEL VC 1350/220 Tech including robot Viper 12 | 220 | Engel | 1 |

| ENGEL VC 860H/200 with ENGEL 2K technology applied | 220 | Engel | 1 |

| ENGEL VC 650H/80V/220 Combi including 6 axis robot KUKA KR6, camera screen and ENGEL 2K technology applied | 220 | Engel | 1 |

| ENGEL VC 750/220 Tech including robot Viper 12 | 220 | Engel | 1 |

| BA 210/750 including robot Wittmann W818 | 210 | Battenfeld | 1 |

| BA Smart Power 180/1000 including robot Wittmann W818 | 180 | Battenfeld | 1 |

| EM 180 SPV/2 | 180 | Chen Hsong | 1 |

| ENGEL VC 330H/80V/160 Combi with ENGEL 2K technology applied | 160 | Engel | 1 |

| ENGEL 650/150 Tech | 150 | Engel | 1 |

| BA 1500/1000 CDC | 150 | Battenfeld | 1 |

| MITSUBISHI 130 Metill (EL) | 130 | Mitsubishi | 1 |

| BA 130/525 TM | 130 | Battenfeld | 1 |

| BA 1300/400 CDC | 130 | Battenfeld | 1 |

| ENGEL VC 500/120 SPEX including robot Viper 60 | 120 | Engel | 1 |

| ENGEL VC 500/120 Tech including picker ER – USP 5 EP4 | 120 | Engel | 1 |

| ENGEL VC 500/120 Tech including robot Viper 20 | 120 | Engel | 1 |

| ENGEL VC 330/120 Tech including robot Wittmann W818 | 120 | Engel | 1 |

| ENGEL VC 330/120 Tech including picker ER – USP 5 EP4 | 120 | Engel | 1 |

| ENGEL VC 330H/200V/120 Combi including robot ERC 13/1-e and ENGEL 2K technology applied | 120 | Engel | 1 |

| BA HM 110/525 including robot Wittmann 818 | 110 | Battenfeld | 1 |

| BA EcoPower 110/350 H (EL) including robot Wittmann W811 | 110 | Battenfeld | 1 |

| ENGEL E-MAX 200/100 (EL) including picker ER – USP 5 EP4 | 100 | Engel | 1 |

| EM 80 SPV/2 including robot Wittmann W811 | 80 | Chen Hsong | 1 |

| BA 60/210 E HM including inlet picker | 60 | Battenfeld | 1 |

| ENGEL VC 80/50 Tech including robot ERC 23F and ENGEL OVM technology applied | 50 | Engel | 1 |

| TOTAL No. of machines | 45 |

IML = In Mould Labeling techonolgy

OVM = Overmoulding technology

2K = Two Plastics Injection technology

EL = electric injection machine